Collection: Spraytech 12V Pump Controllers

Spraytech 12V Pump Controllers - Enabling accurate pump flow adjustment

Pump Controllers: What To Look For

As well as controlling the speed and therefore the output one of the benefits of pump controllers is that they also protect the pump motor and pressure switch.

If you run a 12 volt pump directly from the battery it will on average be drawing close to max amps (7a to 8a) When the flow is closed the pump pressure switch activates under high load and the current will arc across the switch and short out the pressure switch.

At Max amp for several hours a day a pump motor also will become very hot.

As a result users are regularly replacing pressure switches, sometimes several times a year and regularly replacing pumps.

A controller when calibrated will stop the pump well before the pressure switch has to activate. Rather than a pump drawing 8 amps and working very hard. The control means the user can adjust flow to suit the job. In most cases the pump with a controller will move the same amount of fluid but at around 3 amps.

The Pump is now working only as hard as needed and running cooler. As a result the pump motor and pressure switch are protected and their life is extended.

To give a rough comparison a pump run direct from a battery will see the motor reach 50 - 60C with a controller that drops below 40C

Although pumps with a bypass dont have a pressure switch. A controller would still see the pump motor protected as current draw is reduced (3 amps approx) compared to running the pump directly from a battery (7a Or 8 amps)

-

Spraytech Digital Pump Controller with Flow Meter

Regular price £214.50Regular priceUnit price / per -

12V High Current Digital Pump Controller

Regular price £203.50Regular priceUnit price / per -

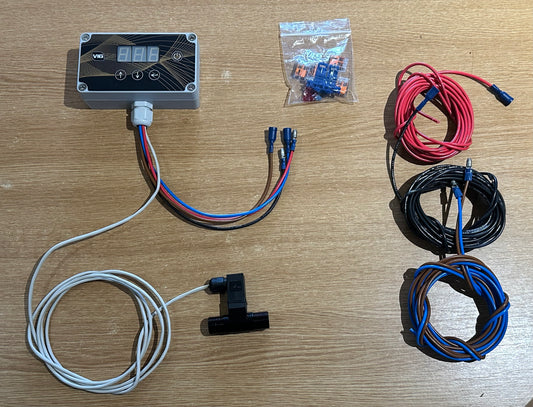

Kit Box Pump Controller

Regular price £152.35Regular priceUnit price / per -

Spraytech Standard Pump Controller

Regular price £96.25Regular priceUnit price / per -

Spraytech Pump Controller

Regular price £31.63Regular priceUnit price / per -

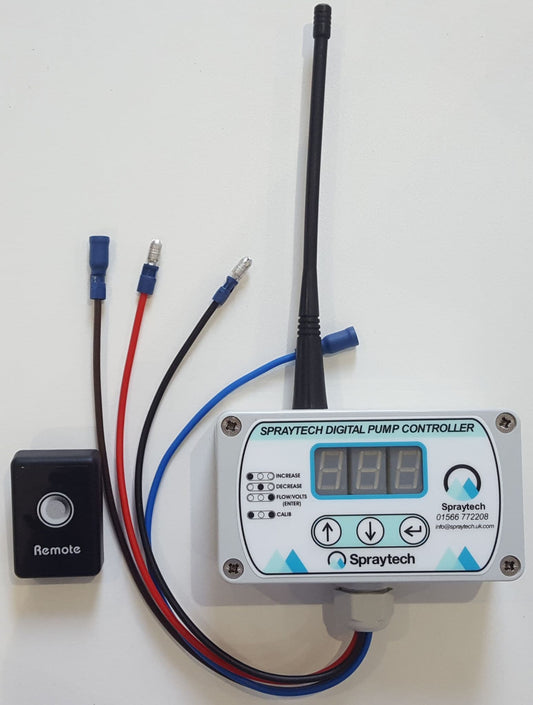

Spraytech Digital Pump Controller w/ Wireless Remote

Regular price £248.05Regular priceUnit price / per -

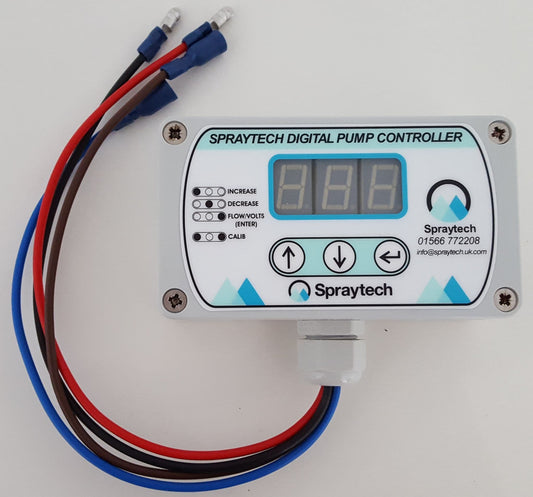

Spraytech Digital Pump Controller

Regular price £142.45Regular priceUnit price / per -

Spraytech Analogue Pump Controller

Regular price £138.05Regular priceUnit price / per -

Spraytech Standalone Wireless Controller Module

Regular price £76.45Regular priceUnit price / per -

Spraytech High Current Digital Pump Controller

Regular price £214.50Regular priceUnit price / per -

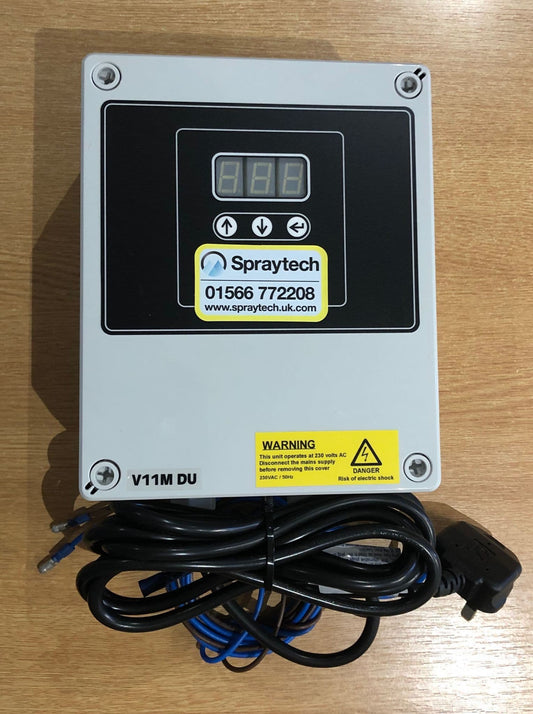

Spraytech Digital Pump Controller w/ Dosing Timer

Regular price From £140.25Regular priceUnit price / per